Setting a good Example

-

> Applications

This is what our Case Studies Reveal

BÜFA Products have proven themselves in Practical Application and they are Impressive

We are one of the leading European developers and manufacturers of specialist reactive resins – and the only system provider with its own machine technology.

Are you looking for a seamless range of gelcoats, topcoats, resins, high-performance adhesives, initiators, mould tooling and fire safety systems for all areas of application? Are you looking for a committed partner with unrivalled expertise? Then you have come to the right place.

See for yourself: read our case studies to find out in detail about our innovative solutions and applications and see what our customers have to say about us.

BÜFA®-Firestop Fire Retardant Systems

As part of a new sustainable solution for the market, BÜFA Composite Systems is proud to showcase a cutting-edge-driver desk at Innovation Planet, manufactured by BKT.

This innovative product utilizes BÜFA®-Firestop-Gelcoat-S 320 in combination with BÜFA®-Firestop S 400 (rPET-based), highlighting a commitment to both sustainability and performance.

BÜFA®-Firestop-Gelcoat-S 320: One Gelcoat for All Requirements!

The BÜFA®-Firestop-Gelcoat-S 320 represents the latest advancement from BÜFA Composite Systems, specifically engineered to meet the stringent requirements of HL3 classification under EN 45545-2, even when painted. Prioritizing both environmental responsibility and safety, this gelcoat is styrene-free, melamine-free, and halogen-free.

Beyond its sustainable composition, the BÜFA®-Firestop-Gelcoat-S 320 delivers exceptional performance, offering the highest Heat Deflection Temperature (HDT) and the lowest Maximum Average Heat Release (MAHRE) available on the market. This unique combination of safety, sustainability, and superior technical properties sets a new benchmark in the industry. To deliver a fully sustainable solution, BÜFA Composite Systems has developed an innovative vacuum infusion resin based on rPET: the BÜFA®-Firestop S 400.

In combination with BÜFA®-Firestop-Gelcoat S 320, this advanced resin not only supports environmental responsibility by incorporating recycled materials but also meets the highest standards for safety and performance.

This system is already certified as HL3 for R1, F7, and R17. In case of any questions, please refer to our fire retardancy experts at BÜFA Composite Systems.

Teamwork: Together we are Strong!

For the production of glass fiber reinforced plastic components, hand lay-up is a simple and widely used process. The hand lay-up process can be used to produce very large and complicated parts, such as machine housing, covers, or even driver's desks. However, this process is also very labor-intensive, thus producing high costs and also creating problems in reproducibility and series production.

Compared to the simple hand lay-up process, the Resin Transfer Moulding (RTM) process offers improved component quality. In addition, the process brings further advantages in terms of automation, such as efficient processes, fast cycle times, high reproducibility, and greater accuracy in the component geometry.

The challenges of the process change from manual laminate to the vacuum infusion process have been taken up by the company BKT (Braunschweiger Kunststofftechnik). Experience in the professional production of composite components is well available here because as a company in the plastics industry, BKT has been producing and supplying well-known customers worldwide for almost 20 years, including those in the rail vehicle, bus, commercial vehicle, special vehicle construction, amusement park, and medical technology sectors.

Effective fire redardant systems are essential wherever large numbers of people are gathered in a small space or where particularly valuable materials have to be protected. In the rail transport, automotive, or commercial vehicle sectors, strict standards must be adhered to. The portfolio of BÜFA®-Fire Retardant Systems is very comprehensive and, thanks to decades of experience, particularly optimized to the needs of the user. The BÜFA®-Portfolio includes optimally matched high-tech GRP systems for maximum lightweight construction, outstanding mechanics, and maximum fire protection.

Implementation

For Siemens Mobility GmbH, the company produces BKT driver's desks for the Desiro HC from the high-performance, modern, and environmentally friendly Desiro train family in the Light RTM Process using the BÜFA®-Firestop Gelcoat GC S 285 and the resin BÜFA®-Firestop S 425. The glass content is approx. 50% (by weight). By covering the mould and counter mould with gelcoat, the desk is also protected against fire on the inside surface as well. By now, this process has become standard at Siemens.

Braunschweiger Kunststofftechnik offers its customers a wide range of services for the development and production of high-quality composite components made of fiber-reinforced plastics. From consulting, design, and construction of the model and mold making to assembly, painting, and logistics. The components are produced using innovative and state-of-the-art manufacturing processes and meet the highest quality standards in compliance with the standards required for each industry.

Finally, a worthwhile look at the gelcoat: BÜFA®-Firestop Gelcoat S 285 delivers the highest fire protection for rail vehicles and is also characterized by increased flexibility and low emission and shrinkage tendencies.

With BÜFA's flame-retardant gelcoats, even layer thicknesses as thin as 800 μm, the strictest fire protection requirements of EN 45545-2 according to HL3 can be achieved (in combination with one of the proven BÜFA®-Firestop Resins).

Customer Testimony

"Converting the main components of the control panel and sun visor from the originally planned hand laminate to the RTM-process has been a particular challenge for BKT, as the limits of the process we were previously familiar with had to be pushed back significantly due to the geometry of the components. The originally planned two-piece sun visor is now produced in one piece, i.e. 'in one shot'. The control panel was very demanding for our mold making department, especially due to the high side walls with the long flow paths. We now achieve reproducibility in the fitting accuracy and weight consistency of the finished products that were previously hardly thought possible. We decided in favor of the BÜFA®-Fire Retardant System because it has already proven itself in previous projects with high requirements for the RTM-process."

Ralf Litzius,

Plant Manager BKT

Meet our expert

Joe Mardoukh

Market Segment Manager - Fire Retardant Products

Phone +49 4402 975395

Mobile +49 160 96967349

joe.mardoukh@buefa.de

Additional Insights from the ID Buzz Project

Practice-Oriented Training

The project demonstrates how young employees are actively involved in innovative development processes. Working side by side with experienced engineers on the tailgate's development, they learn cutting-edge manufacturing techniques, fostering knowledge transfer and enhancing the company's innovative potential.

Innovative Manufacturing Approaches

In addition to technical execution, the focus is on employing sustainable technologies. The use of vacuum infusion combined with bio-based materials shows how modern production processes can produce resource-efficient and high-performance components.

Sustainability and Future Perspectives

The project emphasizes the use of sustainable materials – such as bio-based resins and natural fibers – and underscores the commitment to establish environmentally friendly technologies in automotive production. It illustrates that pioneering concepts for the next generation of mobility are being developed today.

Economic and Ecological Benefits

Optimized processes and reduced rejection rates help lower production costs. The use of renewable raw materials decreases the CO₂ footprint and promotes a greener value chain.

Comprehensive Process Support

BÜFA supports customers from the initial idea through to the final product, including material selection, process optimization, quality assurance, and training.

Long-Term Benefits

With increasing demands for sustainability and efficiency in the automotive industry, the project demonstrates how these goals can be realized in practice today.

Sustainable Mobility

The ID Buzz Tailgate combines state-of-the-art manufacturing technologies with the use of renewable raw materials. It is being developed as part of an innovative VW project at Volkswagen Commercial Vehicles (VWCV) in Hannover. The ID Buzz is recognized as the first fully electric van for families and businesses in Europe – making it the perfect platform to bring forward pioneering ideas for sustainable mobility.

BÜFA has developed a portfolio of bio-based resins and complementary composite solutions that offer a reduced CO₂ footprint while meeting high technical standards. This results in a component that leads in both aesthetics and mechanical performance, significantly reducing its environmental impact.

Manufacturing Process: Vacuum Infusion

Precision Processing

The vacuum infusion process enables precise resin impregnation of the fiber layers. Using controlled vacuum pressure, the resin is evenly distributed, minimizing air entrapment and ensuring a flawless bond.

Optimal Material Integration

Excellent fiber wetting and targeted additive incorporation allow for precise adjustment of processing parameters. This results in a highly robust and durable composite that meets the demands of modern automotive components.

(Refer to BÜFA®-ECO-Resin UP 6889 biobased – technical data and processing guidelines; see also Gelcoat data.)

Detailed Material Components

1. Bio-based Resin: BÜFA®-ECO-Resin UP 6889 biobased

- An unsaturated polyester resin dissolved in styrene, with a certified bio-based content of 70%.

- Pre-accelerated, non-thixotropic, with moderate reactivity and a viscosity of approximately 1100 - 1300 mPa.s (at 20°C).

- Gel time: 50 - 60 minutes; Cure time: 60 - 75 minutes.

- Suitable for hand lay-up, RTM, and infusion processes, and can also be used with natural fibers.

2. Gelcoat: BÜFA®-NPG-Gelcoat-S transparent clear N°4

- Based on an unsaturated ISO/NPG polyester resin dissolved in styrene, this gelcoat provides a highly aesthetic, transparent finish.

- Protects the substrate from weathering and chemical stresses.

- Offers excellent processing properties with a short gel time (approximately 9 - 15 minutes) and cure time (20 - 25 minutes).

3. Fiber Layers

a) Top Layer – FlaxDry BL550

- A woven reinforcement made of 100% European flax (550 g/m²).

- Provides high tensile strength (approximately 65 - 67 MPa) and a Young's modulus of about 7 - 8 GPa.

- Contributes significantly to external stability and visual quality while supporting sustainable material usage.

b) Bottom Layer – FibriMat F450

- A needle-punched non-woven mat made of flax fibers (450 g/m²).

- Offers a balanced combination of tensile strength (approximately 45 - 47 MPa) and flexibility (Young's modulus around 5 - 6 GPa).

- Ensures even resin distribution during the infusion process and enhances structural integrity.

Component Integration

During production, the gelcoat is first applied as a protective and visually appealing outer layer. The two fiber layers are then integrated as follows:

- FlaxDry BL550 (Top Layer): Provides external stability and a high-quality surface finish.

- FibriMat F450 (Bottom Layer): Enhances structural strength and ensures an optimal bond.

The bio-based resin permeates both fiber layers, creating a highly robust and thermally stable composite that meets the demanding requirements of modern automotive components.

Conclusion

By using sustainable materials and creative design solutions, the trainees impressively demonstrated how tradition and innovation can be harmoniously combined in the ID. Buzz Green can be harmoniously combined. This project shows how environmentally friendly approaches can be put into practice in the automotive industry.

Contact

Meet our expert:

Dipl.-Ing. (FH) Sven Glaser

Productmanager Specials & New Business

Phone +49 4402 975 433

Mobile +49 1712126391

sven.glaser@buefa.de

Sustainable rPET-based Formulations for High-Quality Automotive Parts

AOC and BÜFA have supported Quantum Mouldings in the production of high-quality pop-up roof modules for motorhomes. The new BÜFA®-Resin UK UP 1033 RTM (Black) and BÜFA® Resin UK UP 1027 RTM (White) combined with BÜFA®-Neogel3000 series gelcoats were used. The use of rPET-based formulations not only provides mechanical strength and great part aesthetics but also helps to reduce the environmental footprint – a feature that is highly appreciated by customers and consumers.

Quantum Mouldings is an established manufacturer of composite components used in the automotive, transport, industrial, marine, and signage sectors. The company specializes in medium-sized production runs, typically 1,500 to 5,000 parts per year. Its plant in Kidderminster (UK) utilizes several composite processing techniques, including RTM, hand lay-up, and spray-up. Quantum Mouldings has a reputation for delivering high-quality parts that are manufactured with high accuracy and dimensional stability.

Performance Requirements

One of the products manufactured by Quantum Mouldings is a pop-up lifting roof module used in the aftermarket for converting conventional vans of various brands into motorhomes. The optical parts need to combine great color and surface finish with high mechanical integrity and durability.

"In hot summers, the parts can heat up to over 80°C, especially if they are dark in color," explains Mark Young, General Manager of Quantum Mouldings. "It is therefore very important that the parts do not deform and retain their shape when exposed to heat. In addition, the thermal expansion should roughly correspond to the expansion of the steel of the surrounding roof parts."

Robustness of Processing

For this demanding application, the company uses a combination of BÜFA®-Resin UK UP 1033 RTM (Black) & BÜFA®-Resin UK UP 1027 RTM (White), a recycled PET-based formulation used for RTM and vacuum infusion, and Neogel®-3000 series gelcoats from BÜFA. Quantum Mouldings found that the resin was characterized by low shrinkage, resulting in low warpage and good dimensional predictability during processing.

"We have found that the BÜFA®-Resin UK UP 1033 RTM & BÜFA®-Resin UK UP 1027 RTM has a lower exotherm than the products we have used in the past. This contributes to longer tool life, which has a positive impact on cost savings and tool availability," adds Mark Young. "Compared to DCPD resins, the parts can be demolded more easily and quickly. The flexibility to cure the resin with different peroxide types and concentrations allows us to use this product in molds of varying size and complexity."

Better Performance in the Area of Sustainability

The products BÜFA®-Resin UK UP 1033 RTM & BÜFA®-Resin UK UP 1027 RTM are based on recycled PET, most of which comes from post-consumer waste. Around 4,200 used PET bottles are used for every ton of product, ensuring the efficient reuse of a valuable raw material. The products have also been certified by Lloyd's for the neutral version Synolite 4600-G-1.

"We are seeing a lot of interest from our customers in using these rPET-based formulations for their composite parts," comments Fons Harbers, Vice President of Marketing and Sales at AOC EMEA. "Even though the production of rPET-based products requires more effort and additional process steps, we believe it is worth it and helps to reduce the carbon footprint of our customers' products."

"We enjoy working as a team with Quantum Mouldings and AOC to produce parts with a balance of performance and quality at a competitive system cost," says Eddie Putwain, General Manager of BÜFA Composites UK. "The demand for reliable, environmentally friendly products will continue to grow over the coming years. That's why we're ready to help our customers take big steps to improve sustainability performance."

Website: quantummouldings.co.uk

Roof Elements for Effective Fire Retardance and Extreme Temperatures

Highest Temperature Resistance and Effective Fire Retardance

Success in Siemens' Velaro Egypt project

The requirements for the railway industry are constantly increasing, especially when it comes to the temperature resistance of the fire protection materials used. For roof elements that are exposed to strong sunlight, these conditions pose a major challenge, especially in combination with dark-coloured paintwork. It was precisely these requirements that BKT GmbH faced as part of the prestigious Velaro Egypt project of Siemens.

Challenge: Extreme Temperatures and Effective Fire Retardance

For the Velaro Egypt project, BKT GmbH developed and produced various roof elements and the driver's desk for the train. In view of the extreme climatic conditions to which these components would be exposed, it was crucial that the materials had a temperature resistance of up to 80 °C. In addition, effective fire protection was essential, especially in areas where many people come together in a confined space. These requirements represented not only a technological but also a strategic challenge. Working in partnership with BÜFA Composite Systems as a supplier was crucial to ensure the best possible choice of materials and fire protection solutions.

Solution: Customised Material Selection, Precise Production and Effective Fire Retardance

In close cooperation with BÜFA Composite Systems, BKT GmbH focused on innovative materials and state-of-the-art production techniques. The high-performance material BÜFA®-Firestop 8175-W-1, which BÜFA Composite Systems supplied specifically for the requirements of this project, was used for the roof elements in a hand-laminate process. On the outside, BÜFA®-Firestop Gelcoat-S 285 and BÜFA®-Firestop-Topcoat-S 270 unpainted on the inside. The fibre structure consisted of glass fibre mat and fabric, which ensures an optimum combination of strength, temperature resistance and fire protection.

The BÜFA portfolio includes optimally harmonised high-tech GRP systems that stand for maximum lightweight construction, outstanding mechanics and maximum fire retardance. These systems have been specifically developed to meet the stringent requirements of modern rail vehicle construction.

BKT (Braunschweiger Kunststofftechnik) has risen to the challenge of changing the process from hand laminate to vacuum infusion, as it has a wealth of experience in the professional production of composite components. As a company in the plastics industry, BKT has been producing and supplying well-known customers worldwide for 20 years in sectors such as rail vehicles, buses, commercial vehicles, special vehicles, leisure parks and medical technology.To ensure material qualification, a comprehensive test of the tensile and flexural strength was carried out at 80 °C. The values determined formed the basis for the subsequent finite element calculations (FEM), which confirmed that the BÜFA®-Firestop 8175-W-1 supplied by BÜFA Composite Systems was able to achieve a Tg-onset of over 80 °C in accordance with ISO 6721-5. The material was also tested for its fire protection properties and met the strict requirements of the project.

Result: A Milestone for BKT GmbH

For BKT GmbH, this project was the first time that such a comprehensive effort had been made in advance to ensure the temperature resistance and fire protection of the materials. The close cooperation with BÜFA Composite Systems made a significant contribution to the Velaro Egypt project impressively demonstrating that the highest requirements for temperature resistance and fire protection can also be met in the railway sector.

Outlook: Future-Proof Solutions for Climate Change

This project is not only a success for the Velaro Egypt project, but also marks an important step towards future-proof solutions in railway vehicle construction. In view of climate change and the long service life of rail vehicles, the issue of temperature resistance and fire retardance will play an increasingly important role in future projects. BKT GmbH, supported by its partnership with BÜFA Composite Systems, is ideally equipped to meet these challenges and continue to offer innovative and reliable solutions for rail transport in the future.

Finally, a worthwhile look at the product: BÜFA®-Firestop-Gelcoat-S 285 provides maximum fire protection for rail vehicles and is also characterised by increased flexibility and low emission and shrinkage properties.

With the flame-retardant gelcoats from BÜFA, the strictest fire protection requirements of EN 45545-2 according to HL3 can be achieved from layer thicknesses of 800 μm (in combination with one of the proven BÜFA®-Firestop resins).

Master your Biggest Challenges!

The wind industry is understandably one of the fastest growing industries worldwide. Global installed capacity for this clean technology is over 650 GW. And the potential is growing steadily as new markets open up.

Along with that potential, the requirements regarding fire safety, service life, output and areas of application are also increasing: A wind turbine should last 20 to 30 years and be capable of operating in all climate zones (onshore and offshore). That presents challenges for materials and design.

In view of these challenges, product selection is a crucial part of planning and development.

BÜFA Composite Systems offers the right products and systems for wind energy, which meet the requirements and can cope with the increasing load. Our industry experts will be happy to advise you on all questions about selection and processing, based on our extensive expertise.

Our customers make products for the big wind farm manufacturers. We create solutions together. Simply get in touch with us!

High-quality Specialist Composites

Our product range includes innovative composite specialities for the highest quality requirements in terms of mechanical properties, flexibility and fire safety.

The BÜFA®-Bonding Paste portfolio offers optimal products for individual requirements when bonding rotor blades. They are particularly well suited to bonding laminates that are subject to high dynamic loads across a wide temperature range.

ADHESIVE BONDS FOR ROTOR BLADES

The rotor diameter of the turbines installed in Germany in 2019 averaged 119 metres, the hub height 133 metres and the total height 193 metres. The quality of a rotor blade is determined by the reliability of the many bonded joints. Thick adhesive seams are required to bond shells and webs, and the material must not run off sloping walls.

There are also high requirements for temperature resistance (between -40°C and +60°C) and mechanical strength (without formation of cracks).

BÜFA®-Bonding Pastes are based on elasticised vinyl ester resins, which makes them flexible even if temperatures fluctuate At the same time, their excellent strength is impressive – even on vertical surfaces. They can be processed by hand as well as with suitable BÜFA Tec metering equipment.

GELCOATS, TOPCOATS AND RESINS FOR ROTOR BLADES, MACHINE HOUSINGS (NACELLES) AND HUB CAPS

Rotor blades, machine housings and hubcaps are permanently exposed to environmental factors such as humidity, light, temperature, lightning and impact stress. Highly flexible materials with good impact resistance properties are therefore required.

Depending on the production process and later use of the components, we recommend the products from our extensive BÜFA®-Gelcoat portfolio. e.g.:

Very good weathering properties:

BÜFA®-Standard Gelcoats

For inside coating of nacelles in particular:

BÜFA®-Firestop Gelcoats/Topcoats

For laminates with high demands in terms of mechanical strength:

BÜFA®-RTM/Injection Resins

REFISA - Specialist in Rail Vehicles

REFISA is a reference company in the rail vehicle industry which specialises in the manufacture of polyester parts mainly in the rail vehicle sector and has over 30 years of experience in doing so. The company currently works for leading national and European railway construction firms. REFISA has made over 2,500 complete fronts for underground railway trains and trams with an annual production volume currently of 150-200 units. The company has 4 modern productions sites covering an area of 14,000 m², three of which are in the area of Lleida (Spain), and one is in Serbia, from where customers in central Europe are served.

The search for the best Fire Protection

Before the European standard EN 45545 on protection against fire and smoke finally became binding for rail traffic, REFISA carried out a product search to find an alternative to phenol resins, which are used in the manufacture of glass fibre parts.

“We all agreed that we should have an obligation to use systems with resin and gelcoats that not only eliminate toxicity, but also meet the new regulations,” says REFISA. “Having tested several different options on the market without much success, we finally came upon the BÜFA®-Firestop Gelcoat Series S 270 with intumescence technology, which we were able to combine with various resins in manual lamination and infusion processes.”

BÜFA®-Firestop S 285-SV - Intumescent, Pre-Accelerated, Fire-Retardant

Today REFISA uses the latest generation of intumescent filled gelcoats, the BÜFA®-Firestop S 285-SV: a pre-accelerated, fire-retardant gelcoat that was developed for the most important fire safety applications in rail transport.

REFISA explains: “This is a halogen-free, intumescent, fire-retardant gelcoat based on an unsaturated polyester resin that was developed for spray application and which has enabled us to use the flame retardant gelcoats across the board in our company, both for manual production and for infusion and RTM Light.

BÜFA®-Firestop Gelcoat S 285-SV is a very versatile gelcoat that is easy to spray and cures even at low temperatures.

With this gelcoat in combination with various BÜFA®-Firestop resins, we make a range of parts throughout Europe such as roofs, channels and fronts for underground trains and trams and undercarriages for high-speed trains, where the requirements regarding fire and smoke and their behaviour in load tests are very restrictive.”

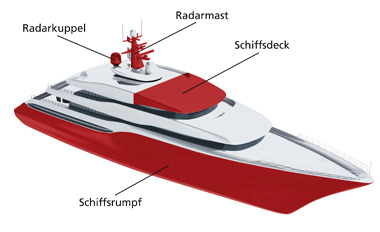

Astondoa Superyacht AS8 – A Masterpiece of the Seas

It sits in the water, majestic and sleek: the latest AS8 superyacht in the Spanish boatyard of Astondoa. Since October 2020, this masterpiece of modern design has been making its way over the seas. At 25.25 metres, it is the biggest yacht in Astondoa’s Flybridge series and combines aesthetics with sporty functionality.

For optimal resilience and durability, the hull of this light boat is made of an infusion glass fibre laminate with Kevlar® reinforcement. Products of outstanding quality are required to protect this basic framework and ensure that the AS8 and its sisters will be able to ride the high seas for many years to come. The Spanish Astondoa boatyard relies on BÜFA’s specialist composite products, which have been certified for the construction of superyachts for over 10 years, and on the professional advice of our employees on site.

Marine quality: BÜFA®-Gelcoats & Bonding Pastes

For the construction of the AS8, Astondoa opted for low-styrene BÜFA gelcoats, in combination with the wide range of BÜFA bonding pastes. These are characterised by excellent weathering and working properties and very good mechanical features.

Advantages of BÜFA®-Gelcoats at a Glance

- Low styrene emissions

- Very good working properties

- High-quality surfaces

- Outstanding weathering stability

- Excellent mechanical properties

Versatility of BÜFA®-Bonding Pastes

Astondoa used various types of BÜFA bonding pastes for its diverse and specific requirements:

- VE bonding pastes (e.g. for hull and deck bonds)

- Bonding pastes for sandwich constructions (e.g. for bonding foams or balsawood)

- Universal bonding pastes for wood, metal and GRP bonds

- Special solutions to avoid air pockets behind the gelcoat

Would you like to see the results? Then get a taste of the maritime lifestyle and watch the first launch of the AS8 hull. For further information, please visit www.astondoa.es

A joint project of Astondoa and BÜFA

Pioneer of the Composites Industry

LLC “Composite Group” is currently one of the leading private companies in Russia in the composites industry. Among other things, the company makes fire safety panels for the construction, rail and commercial vehicle industries and for technological equipment.

The company is also continually developing new opportunities for using composite products with new properties and application areas. For example: fibreglass sandwich panels, panels with integrated polymer heating systems, products based on sprayed “artificial stone”, chemically resistant tanks with complex shapes and products with special physical and mechanical properties.

Petrol Station in the Ice

In 2018 LLC “Composite Group” was given the challenge of making a glass fibre dome with an orange gelcoat (BÜFA®-ISO-Gelcoat 3000). The intention was to protect winter sports enthusiasts when filling up their snowmobiles and shelter the temporary fuel store from the wind and cold. When the 64th “Russian Antarctic Expedition” spent the winter at Vostok Station, the first scientific and climatic tests of a glass fibre dome of this sort were carried out. The dome was installed in a snow-covered area in order to assess the effects of the harsh climatic conditions of the Antarctic on the material.

BÜFA®-ISO Gelcoat 3000 can withstand extreme cold and UV radiation.

In the summer months (February-April 2019), the dome was exposed to strong ultraviolet radiation (“hole in the ozone layer”) and the effects of low temperatures (average temperature -74°С and minimum -82°С) and in the winter months, to the abrasive effects of needle snowflakes in winds of up to 20 m/sec. According to S.F. Vasyutkin, General Director of “Composite Group” LLC, the feedback from the Russian scientists shows that the composite material of the dome with a gelcoat layer of BÜFA®-ISO-Gelcoat 3000 withstood all of the factors mentioned above without altering the material, including the degree of gloss. The dome is still being used by employees at Vostok Station in a long-term test at low temperatures and in strong UV radiation.

Product advantages of BÜFA®-ISO GELCOAT 3000

The BÜFA range includes a multitude of gelcoats for a wide range of application areas. As Europe’s leading provider of gelcoats, BÜFA invests continuously in the development of its product range. BÜFA®-ISO Gelcoat 3000 has many advantages.

Benefits at a Glance:

- Unique colour accuracy

- UV-resistant

- Extremely weather-resistant, with high gloss retention

- REACH-compliant

- Manual and spray application possible

- Available types: gelcoats and topcoats

With application by hand (BÜFA®-ISO-Gelcoat 3000-H), it is possible to apply the gelcoat in one stage because of the higher working viscosity (compared to the 3000-S). BÜFA®-ISO Gelcoat 3000-S (spray application) impresses with its good thixotropic behaviour without pigment separation.

Gelcoats and topcoats

Entry into Sustainable Sailing

Success stories make the difference between stagnation and progress. At a time in which environmental responsibility and innovation both play increasingly ma- jor roles, BÜFA Composite Systems, as a specialist supplier of polyester resins, and KHULULA, as a trailblazer for sustainable progress in sailing, have joined forces.

In early 2022 KHULULA presented the ‘Eco_Optimist’ – a highly remarkable sailing boat and the first of its kind, built predominantly from renewable and recycled materials.

The visionaries behind this environmentally friendly optimist are Simon Licht and Holger Ambroselli of KHULULA. Their idea led to the formation of the Eco_ Team Race Germany, the world’s first sustainable, transparently documented sports series for children. The long periods of operation and the intensity of use during these races has emphasized the real performance of the boat.

BÜFA Composites provided an biobased resin, flax as a natural fibre reinforce- ment and a strong sandwich core in recycled PET, which formed the basis for the project. Simon Licht of KHULULA commended the decisive support provided by BÜFA, which formed the basis for the environmentally friendly boat and support- ed KHULULA’s efforts towards sustainable innovation in sailing.

Implementation of the Eco_Optimist was handled professionally by Tobias Schadewaldt and his team from Jade Yachting. The good, straightforward fab- rication properties of the materials supplied by BÜFA Composites in the closed- mould process were confirmed, which contributed to the efficient and precise manufacturing of the boats. Thanks to production in Germany using accessory parts from Europe, lengthy sea transport could be avoided.

The result is an environmentally friendly ‘Opti’ class dinghy in fibre composites with hydrolysis and UV resistance made with about 90% renewable raw materi- als and recycled materials. BÜFA provided support not only with its products but also during the production phase since the first prototype was produced in the application technology department of BÜFA Composites. The result shows that sustainability and performance can go together.

The integration of bio resins, natural fibre reinforcements and recycled PET sandwich cores as sustainable individual components or as part of an integrated sustainable system opens up exciting prospects for the future. These solutions could set new benchmarks for environmental friendliness and efficiency in many branches. The future looks promising as more and more companies are seeking sustainable solutions for making their products and processes more environ- mentally friendly.

Welcome to Hatcher

Hatcher Components Ltd. specialises in designing, developing and manufacturing aerodynamic and design solutions for commercial vehicles using glass fibre reinforced plastics. The range of customers served by Hatcher Components in the UK and Europe runs from leading manufacturers to end consumers.

Hatcher Components Ltd. has been manufacturing GRP components for 50 years and using BÜFA materials, delivered by BUFA Composites UK, for over 20 years:

all the production tools are made with BÜFA®-VE Tooling Gelcoat in hand quality. The BÜFA®-ISO Gelcoat 3000 range is used in spray and hand versions with GRP components.

Customised Aerodynamic Production

With its specialisation in the design and development of external cab spoilers, Hatcher optimises the aerodynamics and fuel consumption of vehicles.

The tailor-made cab suspension devices (vehicle interior) fit completely to the back of the cab roof and do not affect the space for the bunk underneath. When fitted, the devices look as if they were installed in the factory, as they match the style and colour of the interior completely. The subdivided compartments with lockable doors offer an additional secure space solution of up to 500 litres, depending on the design, and are equipped with gas cylinders.

High-quality Moulds and Superior Colour Stability

In response to the question “Why BÜFA?”, Neil Smith, Head of Operations at Hatcher Components Ltd., says:

“With BÜFA®-VE Tooling Gelcoat, we are able to make high-quality moulds. The development time for new products is cut and the tool surface is significantly improved at the same time. BÜFA®-ISO Gelcoat 3000 guarantees that the components, which are exposed to the worst weather conditions every day, have superior colour stability and high gloss durability. The capacity to achieve colour combinations quickly here in the UK, combined with the short material lead time from BUFA Composites UK, makes it possible to adapt rapidly to continually changing customer requirements. The hand version of the BÜFA®-ISO Gelcoat 3000 is used for manual application, the BÜFA®-ISO-Gelcoat 3000 spray version is used with the BÜFA®-Tec GSU ES1 Machine on the RTM production line.”

Product advantages of BÜFA®-ISO GELCOAT 3000

The BÜFA range includes a multitude of gelcoats for a wide range of application areas. As Europe’s leading provider of gelcoats, BÜFA invests continuously in the development of its product range. BÜFA®-ISO Gelcoat 3000 has many advantages.

Benefits at a Glance:

- Unique colour accuracy

- UV-resistant

- Extremely weather-resistant, with high gloss retention

- REACH-compliant

- Manual and spray application possible

- Available types: gelcoats and topcoats

With application by hand (BÜFA®-ISO-Gelcoat 3000-H), it is possible to apply the gelcoat in one stage because of the higher working viscosity (compared to the 3000-S). BÜFA®-ISO Gelcoat 3000-S (spray application) impresses with its good thixotropic behaviour without pigment separation.

A collaborative project of Hatcher Components, BUFA Composites UK and BÜFA

VDL Bus & Coach – Sustainable Mobility

Clear lines, technically sophisticated functions, high-quality materials and a low-maintenance, fuel-saving lightweight design characterise the range of coaches from VDL Bus & Coach. The coaches offer maximum comfort in all situations: from day trips to first-class long-distance travel. The city and overland buses developed by VDL Bus & Coach are produced for the international public transport market.

With an eye to the future and in line with its efforts to achieve sustainable mobility, VDL Bus & Coach is working continuously on improving its products and production processes. The aim is to provide mobility for everyone. People are at the heart of both the company and its products. In particular, the light dead weight of the buses from VDL Bus & Coach ensures optimal performance and maximum yield for its customers.

So light! – with BÜFA-Foaming Resin Systems

BÜFA’s own foam resin systems (BÜFA-Foaming Resin Systems) are just made for lightweight commercial vehicles such as buses from VDL Bus & Coach. The foam resin systems from BÜFA offer:

- Safety in relation to fire protection

- Weight reduction of up to 45%

- Efficient and fast to work with

- Economic advantages

- First-class surface quality

In order to work with BÜFA®-Foaming Resin Systems, you require a BÜFA foam resin that meets your needs, BÜFA’s own blowing agent and peroxide. We will be happy to advise you on suitable products and the right processing.

A joint project of VDL Bus & Coach, OMB and BÜFA

EIKBOOM GmbH – GRP Components for Various Sectors

The Rostock-based company EIKBOOM GmbH is a medium-sized, family-run business that specialises in supporting its customers with every phase of the product life cycle – from development to serial production. The GRP components of EIKBOOM are used, for example, in wind turbine and cooling tower construction and in creating aesthetic architectural solutions and solving technical tasks with special designs and surface structures.

In 2005, EIKBOOM was involved in the prototype construction of the nacelle for Germany’s first near-shore turbine – the largest offshore wind turbine in the world at the time. In addition, the manufacturer supplies high-quality components made of fibre-reinforced plastics for vehicle, boat and ship construction, the food, sports and leisure industries, plant engineering and many other sectors.

By Professionals for Professionals

EIKBOOM offers the right machinery and processing technology for both open and closed-system processes. Quality is monitored continuously in accordance with the requirements of DIN EN ISO 9001:2015. Using a CNC-controlled processing centre, EIKBOOM also offers its customers high-precision processing of components with unusual tolerances. EIKBOOM specialises in manufacturing and supplying vehicle body components and interior GRP parts to the automotive industry. EIKBOOM is fully aware of the advantages of fibre-reinforced plastic in terms of lightweight engineering and shape design and puts its trust here in the BÜFA®-Tooling System:

“The new antistatic BÜFA®-Conductive Tooling Gelcoat and the BÜFA®-Mould Tooling Resins can be processed effortlessly. Safety is an important consideration for us – the conductive system helps prevent electrostatic discharge during demoulding. Another crucial factor is that the system produces high-quality surfaces. This system is an absolute asset,” says Meyk Rohde, Head of Sales at EIKBOOM GmbH.

BÜFA-Tooling System – Cost-effective and Conductive

For even better tools within a shorter time and with an extremely cost-effective process: the new BÜFA Tooling System is a revolutionary mould making system based on the latest findings in polymer chemistry. The following components make up the BÜFA Tooling System:

- 1. The conductive BÜFA®-Conductive-Tooling Gelcoat

- 2. BÜFA®-Resin VE 0910 first-layer resin

- 3. BÜFA®-Resin VE 7100 low-profile tooling resin

The material is processed with the BÜFA®-Tec ES 1 Easy Lift Gelcoat Spraying System. The new BÜFA®-Tooling System saves you time, uses less material and even protects the environment. With first class mechanical characteristics and high-gloss surface finishing, you can improve your product quality enormously. In addition, the conductivity of the tool makes a significant contribution to occupational safety.

Advantages of the BÜFA-Tooling System at a Glance

- Increased process reliability

- Reliably prevents electrostatic build-up and discharge

- Minimised dust adhesion

- Significantly reduced cycle times

- High-quality component surfaces with significantly reduced ripple effect

- Significantly better value for money

In particular, the BÜFA®-Conductive Tooling Gelcoat offers the following advantages in addition to the usual properties of a tooling gelcoat:

- Electrically conductive (TÜV-certified)

- Additional safety (use in EX-zones 2, 1 and 0)

- Better component quality

- Faster cycle times thanks to a reduction in cleaning steps

- Longer service life for tools

- New opportunities for innovative processes

- Ideal working properties

- High gloss and optimised surface stability

- Less work required to maintain moulds

A joint project of Eikboom and BÜFA

Europool – All-round Service for Swimming Pleasure

Europool, a company from Poland (Mogilno), builds GRP swimming pools and is a long-standing customer of BÜFA. Europool offers its customers a Europe-wide, all-round service from manufacture of the pool to assembly, installation, accessories and fast customer service. There are several pool variants. From garden pools that have been for sale in Baumarkt since the beginning of 2018 to more complex, individual, luxury solutions. For the highest surface quality of its pools, Europool relies on BÜFA®-Swim NPG Gelcoats in various colours. These gelcoats are applied by spray. Europool also uses BÜFA®-Resin VE for the manual lamination and fibre spraying process.

BÜFA-Swim-NPG Gelcoats are Impressive

“With the aim of offering our customers professional products of the highest manufacturing quality, we have opted to use BÜFA products over many years. The high quality standards of BÜFA’s processing materials and the effective on-site support are a guarantee of good collaboration,”says Krzysztof Rakowski (Managing Director of Europool). “Pools made of fibre-reinforced plastics, the production and assembly of which requires far less time and money than swimming pools made of reinforced concrete, are also very easy to customise.”

Follow the example of Europool: BÜFA supplies an extensive product portfolio for pool construction worldwide and offers you a large selection of individual production options. As a system supplier, BÜFA also offers the appropriate bonding pastes and machine technology for optimum processability.

BÜFA Tec

Step by Step to the Optimal Surface

Double holds better, three layers really do the job. These 3 layers help to give the pool the optimal surface and reliable resistance to osmosis:

1. Gelcoat

We recommend BÜFA®-Swim-NPG (art. no. 752-colour) with maximum resistance to osmosis. Working temperature: maximum 35°C.

2. Barrier coat or First Layer of Resin

Barrier Coat

BÜFA®-VE Barriercoat SV, beige, in the spray version (art. no. 722-1966) is suitable as a barrier coat.

This additional gelcoat layer based on a vinyl ester resin improves the surface quality and resistance to osmosis and is therefore strongly recommended.

First Layer of Resin

Alternatively, use BÜFA®-Resin VE 0910 (art. no. 700-0910), a pre-accelerated, thixotropic resin with standard MEKP curing. This is perfect as the first layer of resin.

3. Completion of the Laminate

SYNOLITE 8388-P-1 (art. no. 770-8388) is the medium of choice to build up and complete the laminate after the first layer of resin.

A joint Project of Europool and BÜFA

INTERTEC – Protection against Harsh Conditions

INTERTEC is a supplier of unique systems that offer reliable protection for highly sensitive field instrumentation. They protect systems that operate under tough conditions throughout the world – in the Arctic, in the desert and, of course, also in Europe. More than half a million INTERTEC protection systems of this sort help instruments, analytical devices, mobile phone and radar equipment, signal systems, transmitters and much more operate smoothly and without risk.

Extensive expertise in engineering and innovation, e.g. in explosion protection, fire prevention and safety technology, have allowed INTERTEC to grow into a world leading manufacturer in this segment.

The individually adaptable INTERTEC protection systems consist of GRP sandwich elements with inside and outside layers and a core of thermally insulating PU foam. They combine strength and rigidity with protection against harsh environmental conditions that is well above the average.

BÜFA CONDUCTIVE Gelcoats – Perfect Teamwork

For this, BÜFA Composites supplies the new and innovative BÜFA®-CONDUCTIVE Gelcoats, which are based on nanotechnology and thus have outstanding properties in the area of conductivity and processing optimisation.

“BÜFA®-CONDUCTIVE Gelcoat, a high-tech material, offers unbeatable advantages for manufacturing protective systems in explosion protection areas (in accordance with IEC, ATEX, CSA, GOST, Nepsi) and for use under tough environmental conditions with high mechanical requirements,” says Walter Gabler, Technical Director at INTERTEC.

“Our customers include almost all the best-known companies in the areas of energy, chemicals and engineering in the world. They trust us when it comes to protecting highly sensitive instruments and control devices against extreme loads – with high-tech housings and heating or cooling systems from INTERTEC.”

The two companies are linked by decades of collaboration, from which BÜFA®-CONDUCTIVE Gelcoats emerged as a joint project.

Conductive, Innovative, Versatile

BÜFA®-Conductive Line products offer completely new possibilities for applications requiring low electrical resistance.

“BÜFA-ISO-Gelcoat-SV conductive grey” is the new generation of conductive gelcoats in the BÜFA portfolio. Their outstanding conductivity is achieved by the addition of very small quantities of single-walled CNTs. In comparison to conventional materials based on carbon black, graphite or carbon fibre, the quantity used is around 300 times less; compared to standard multi-walled CNTs, 30 times less. With the new technology, resistors can be set variably in a range from 10 to the power of 9 to 10 to the power of 2 Ohms. This opens up many new possibilities and advantages.

Appearance, Processing and Process Reliability

Externally, the BÜFA-CONDUCTIVE Gelcoats range from new, previously unattainable colours to translucent gelcoat formulations. Visually, the new formulation cannot be distinguished from normal, non-conductive materials. The low amounts required makes high-gloss components possible. The working properties are maintained, so normal processing machines can be used. The viscosity figures are at normal/standard levels. This ensures much better de-airing compared to conventional materials. Because of the smaller proportion of pigment, there is no longer any significant negative effect on curing behaviour. In order to ensure high process reliability, the conductivity values can be reproduced from one component to the next. The fine distribution of nanoparticles in the gelcoat gives uniform conductivity values.

Product Benefits at a Glance:

- Constant electrical conductivity, adjustable from 10 to the power of 9 to 10 to the power of 2 Ohms.

- Can be used with electrical heating elements (resistance heating)

- Low concentration of functional additives makes a wide range of colours possible

- Translucent and available in various colours

- Antistatic

- Process reliability/easy processing

- Low viscosity for optimal processing

You can see the potential applications for the complete range of BÜFA products for processing composite materials here.

Industries

A joint Project of INTERTEC and BÜFA

Astondoa – a Passion for the Sea

Astondoa is based in Santa Pola – with a view over the sea and just 10 minutes away from Alicante airport. Yachts measuring up to 122 metres in length are made there in an area covering over 30,000 m².

Its passion for manufacturing and designing yachts began back in 1916. Now in its third generation, Astondoa serves the leisure sailing sector as the largest boatyard for yachts and boats in Spain and one of the largest in Europe. 100 years of experience are the basis for and guarantee of its current strength in technology, design and innovation. It has already built over 3,000 boats and its production figures currently touch 100 units a year – with models and functions for every taste. Attractive designs, equipped with modern technology, are the essence of the Astondoa philosophy, which is defined by smooth lines, styling, decoration and optimal use of space, both inside and out.

In the production process, particular emphasis is placed on avoiding emissions and pollutants.

Astondoa Century 110 – naturally with BÜFA

Astondoa builds boats that spark the instinct for adventure, without sacrificing luxury or refinement. This is the unmistakable stamp of the company.

To mark 100 years of the company’s history, Astondoa has launched a new line of large luxury yachts: Astondoa Century. The first model in this new line is the Astondoa Century 110, a 110-foot yacht with a flybridge, a total length of 33.5 metres and a width of 7.03 metres. The Century 110 is just one of the many masterpieces for which Astondoa has used BÜFA materials over more than 10 years. Out of a belief in the quality of BÜFA® products and the professional advice of our employees on site. BÜFA®-Gelcoats and BÜFA®-Bonding Pastes have proven themselves over many years. BÜFA®-Tooling Gelcoat, Neogel-Gelcoat, BÜFA®-Bonding Paste 0051 and 0110 and BÜFA®-Paraffin Solution were also used in the manufacture of the Century 110.

BÜFA Bonding Pastes

BÜFA – Predestined for Boat Building

Boat building is an important area of application for fibre reinforced plastics. Individual parts, whole decks and complete boat hulls for sailing/motor yachts and powerboats are made from high-quality GRP. The quality of the gelcoats used must meet the highest demands, given the permanent exposure to sun and sea water and repeated surface treatment by the boat’s owner. Characteristics such as colour accuracy, osmosis resistance and surface gloss are important material attributes.

Along with gelcoats and topcoats based on ISO/NPG and ISO, BÜFA Composite Systems has a wide product range of high-quality bonding pastes ready for delivery. These include high-quality VE bonding pastes (e.g. for hull/deck bonding), bonding pastes for sandwich constructions made from foams and balsawood, universal bonding pastes (for wood, metal, GRP bonds) and highly specialised solutions (e.g. “liquid glass mats” to prevent air gaps behind the gelcoat).

You can see the potential applications for the complete range of BÜFA products for processing composite materials here.

A joint project of Astondoa and BÜFA